Head Office

19A Tombia Street, GRA, Port Harcourt, Nigeria

Canada Office

65 Aspenshire Drive, SW Calgary, Alberta, Canada

Fabrication Yard

Along PH/Owerri Int’l Airport Road, Omagwa, Port Harcourt, Nigeria

Inquiries

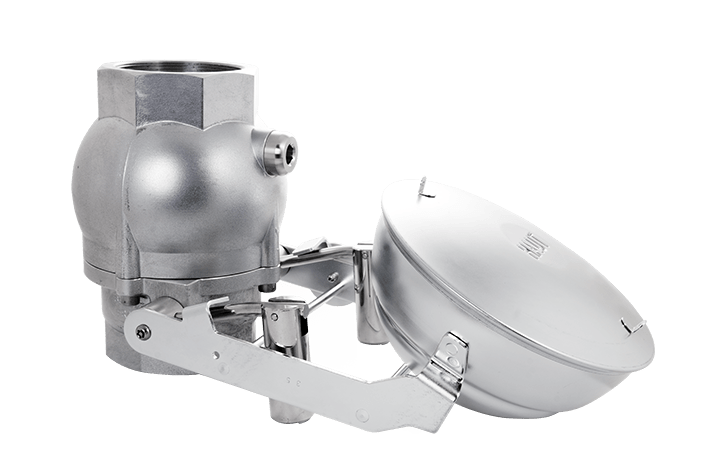

ESD Valves

The Saf-T-Matic is an essential component for all flow line applications. This is a highly dependable safety valve which automatically controls the shutdown of flow lines when pressures exceed or fall below, pre-determined limits.

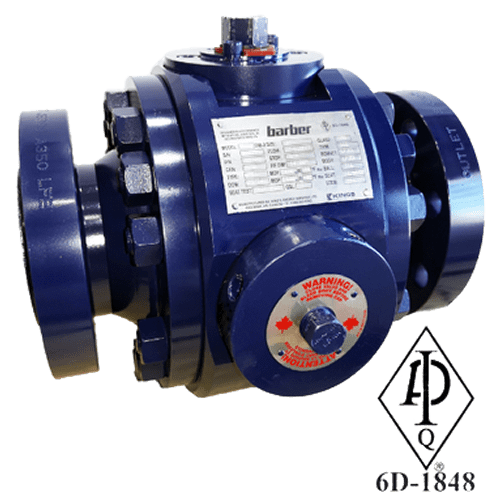

Pigging Valves

Kings Energy Services holds all manufacturing, distribution, patent, and trademark rights to the Barber Pigging Valve. Kings Energy manufactures Barber pigging valves ranging in size from 2" through 8".

Ball Valves

The FLO-KING ball valve is exclusively manufactured and distributed by King's Energy Services. This valve addresses the problem of inline reparability with a new and innovative design, REDUCING DOWNTIME and REVOLUTIONIZING FLOW!

Process Instrumentation CalBenches

CalBenches for process, pressure and temperature instrumentation calibration.

Electrical Calibration CalBenches

CalBenches for calibration of engineers test tools, meters, and electrical safety testers.

Instrumentation Training CalBenches

CalBenches for instrument engineer and technician training and education.

Pressure Calibration CalBenches

CalBenches for calibration of pressure devices such as gauges, transmitters, switches.

Leak Detector LWG 2000 for Tanks & Bunds

The LWG 2000 is a leak detection system for monitoring single or double-walled tanks, pipes and drip pans in installations for storing, filling and transferring polluting liquids.

Tank leak detector Fuitalarme 16 SC.R for double-walled tanks

The Fuitalarme 16 SC.R is a leak detector for double-walled tanks, the interstitial space is filled with a leak detection fluid (usually monoethylene glycol). These tanks are generally used for the storage of flammable or water-polluting liquids that may belong to risk groups and classes AI, AII, AIII and B.

Overfill prevention device for petroleum fuels 2″, 3″ and 4″ N type

The overfill prevention device N type for liquid petroleum fuels offers total safety and guarantees maximum protection for the environment by preventing any risk of overflow when filling static storage tanks.

Overfill prevention device for the chemical industry 2″ and 3″ NT type

The overfill prevention valve NT Type for chemical liquids is a mechanical overfill protection device with total safety preventing all risks of overflow during the filling stage of storage tanks.

Flare Gas Meters

Kings Energy Focus 2.0 flare gas optical flow meter utilizes the state-of-the-art L2F Velocimetry technology. Focus 2.0 OFM uses precise lasers to measure the gas flow by sensing the velocity of microscopic particulates naturally occurring in gas.